Alloy Wheel Refurbishment Systems

Why Choose Us for Alloy Wheel Spray Booths?

Initial Contact

Our process starts with an open dialogue to understand your business objectives and operational needs, whether you're launching a new alloy wheel refurbishment plant or expanding an existing one. Initial details like booth size or extraction options aren’t critical at this stage. Our priority is aligning with your goals to design a fully integrated system that suits your business. We provide an outline of costs and timelines early on, with starter systems beginning at £15,000 and more advanced setups, including diamond-cutting lathes, exceeding £100,000. This clear and transparent communication builds trust from the outset, laying the groundwork for a strong, collaborative partnership that ensures long term success.

Precise Alloy Wheel Plant Design

The success of any alloy wheel refurbishment system lies in precise design, tailored to specific needs. We start with an on-site assessment to understand your operations, spatial constraints and goals. Our engineers use advanced software to create models that not only visualise the layout but also simulate flow, ensuring full compliance with health and safety guidelines and local building codes. These models allow us to adapt to evolving industry standards, ensuring an optimal solution for both present and future needs. We take pride in offering flexible, forward thinking designs that account for safety, environmental impact, and energy efficiency, all while being scalable to grow with your business.

Alloy Wheel Spray Booth Choice

Spray booths are central to alloy wheel refurbishment, providing a controlled environment that protects painted surfaces and ensures efficiency. Often integrated with curing ovens in an enclosed environment, they ensure a seamless workflow from spraying to curing. We offer both manual and automated booths designed to meet your production scale, available in open or enclosed formats with either dry filter or water-backed extraction systems. High-efficiency exhaust solutions, adaptable to your facility’s layout, maintain air quality and meet environmental standards. Customisable lighting options enhance precision during the spray process, ensuring each booth aligns with your quality requirements. These systems are integrated seamlessly into your operations, optimising workflow for long term reliability.

Alloy Wheel Curing

Curing is essential to achieving a durable, high-quality finish for alloy wheels. Our box ovens are engineered to provide even heat distribution, eliminating inconsistencies across all wheel sizes with advanced temperature control systems. These ovens are customisable for any production scale, ensuring precise curing. Available with electric or gas heating options, they feature multi-sided air input systems for uniform heat throughout the chamber. To ensure consistent quality, optional realtime monitoring can track key parameters like temperature and airflow, giving you full control over the process. Integrated conveyor systems can streamline the movement of wheels from spray booth to oven, reducing manual handling and boosting efficiency. Choosing the right combination of booth and curing is critical during the design phase, prior to manufacture.

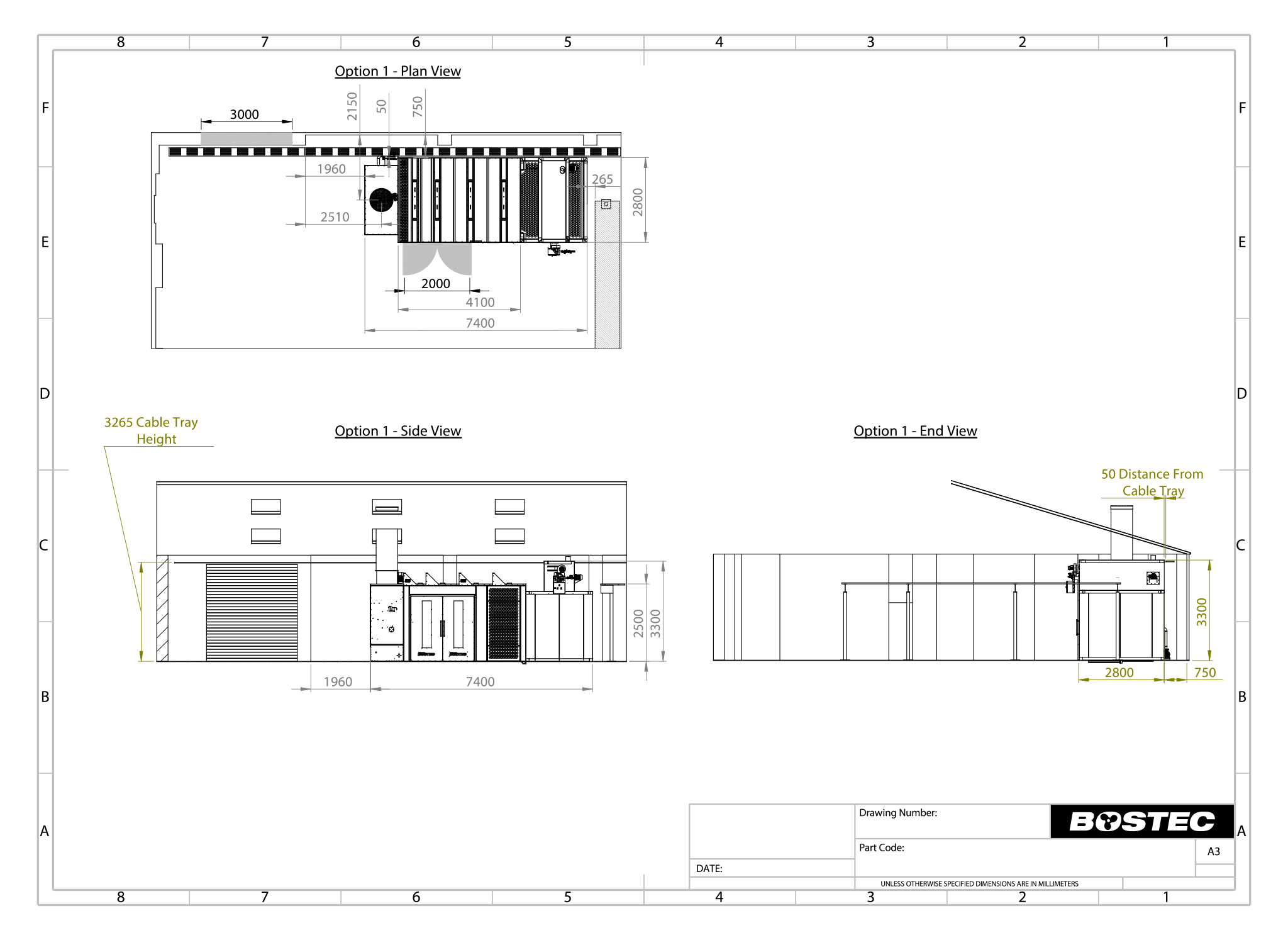

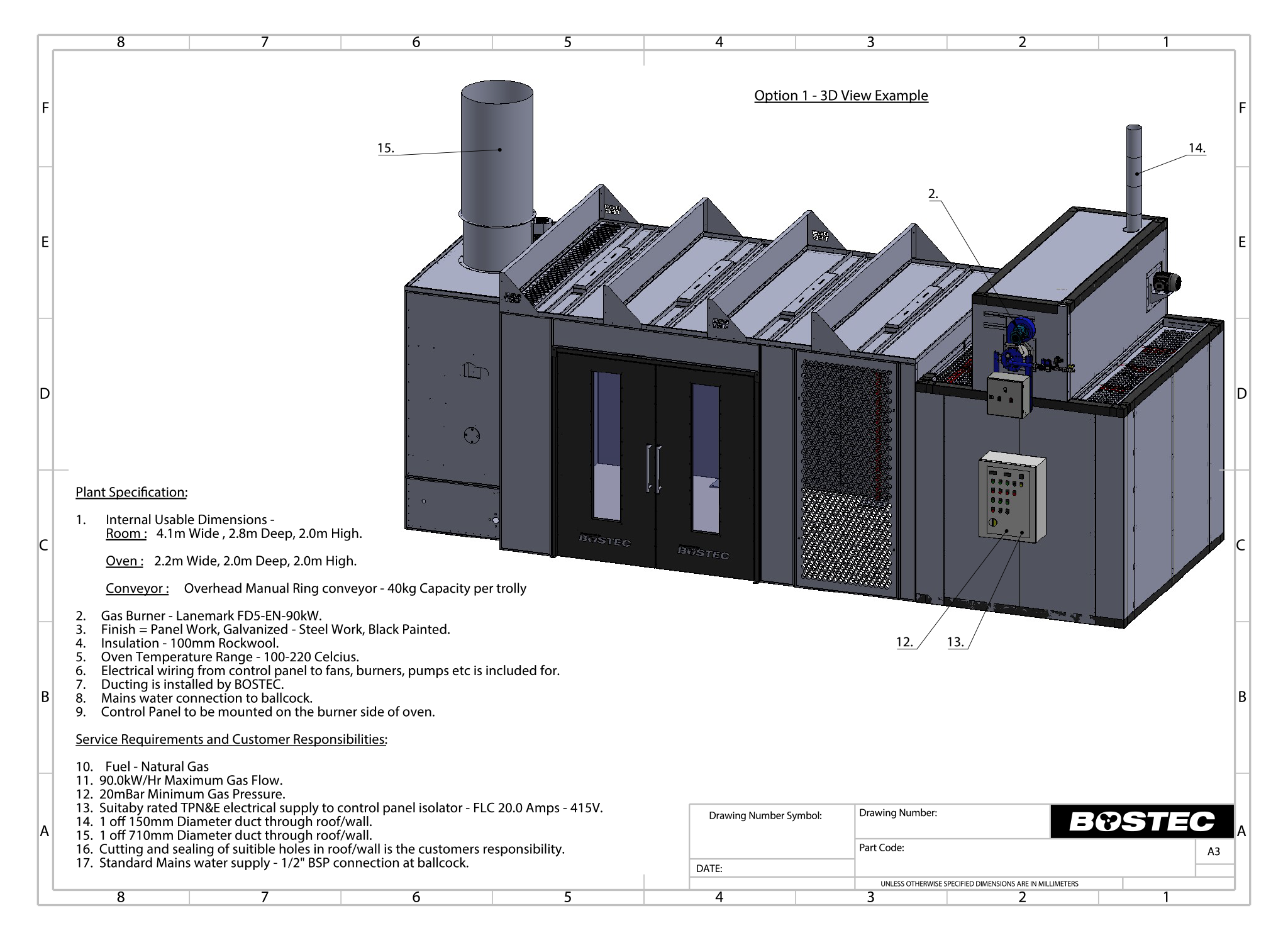

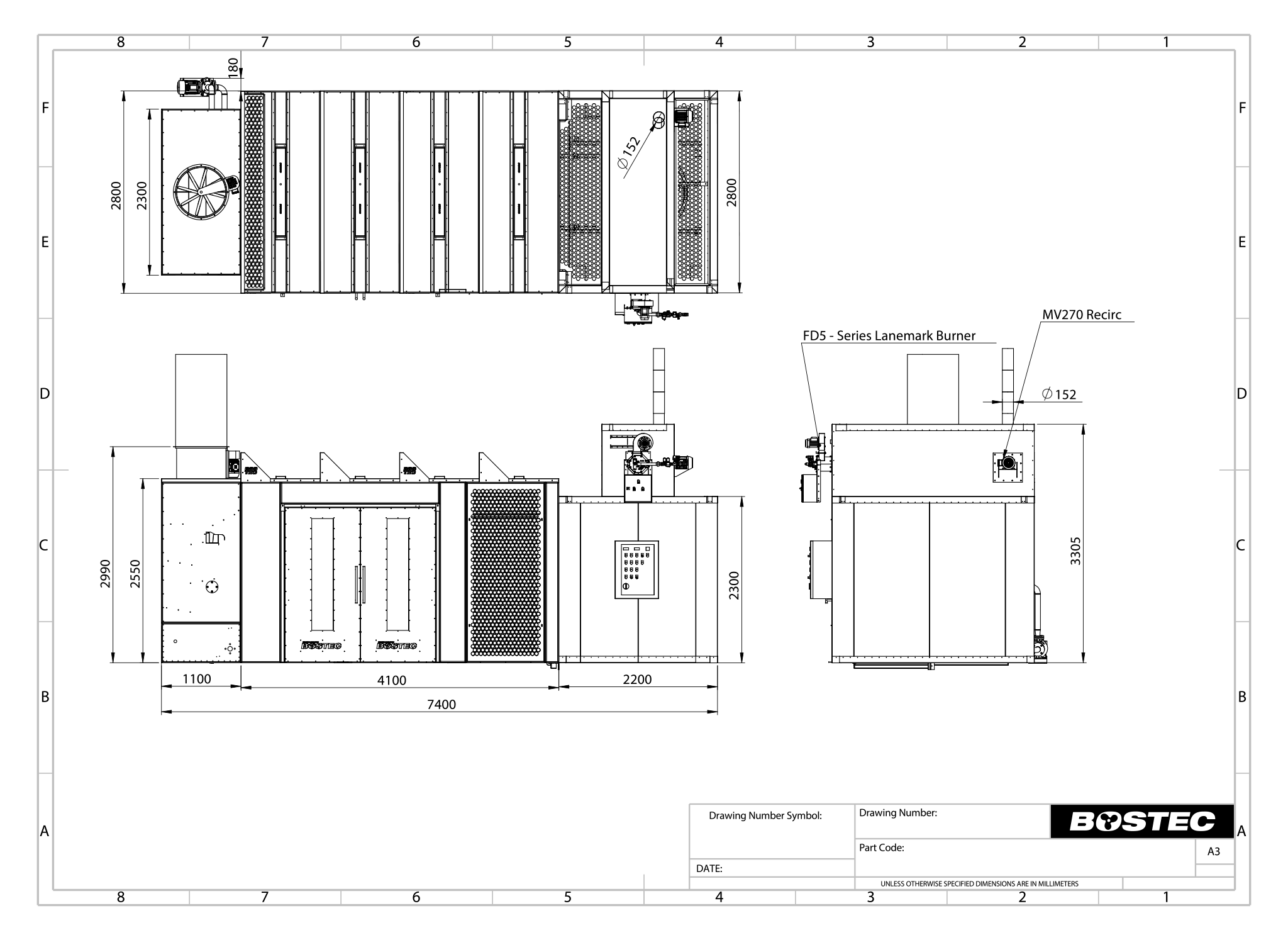

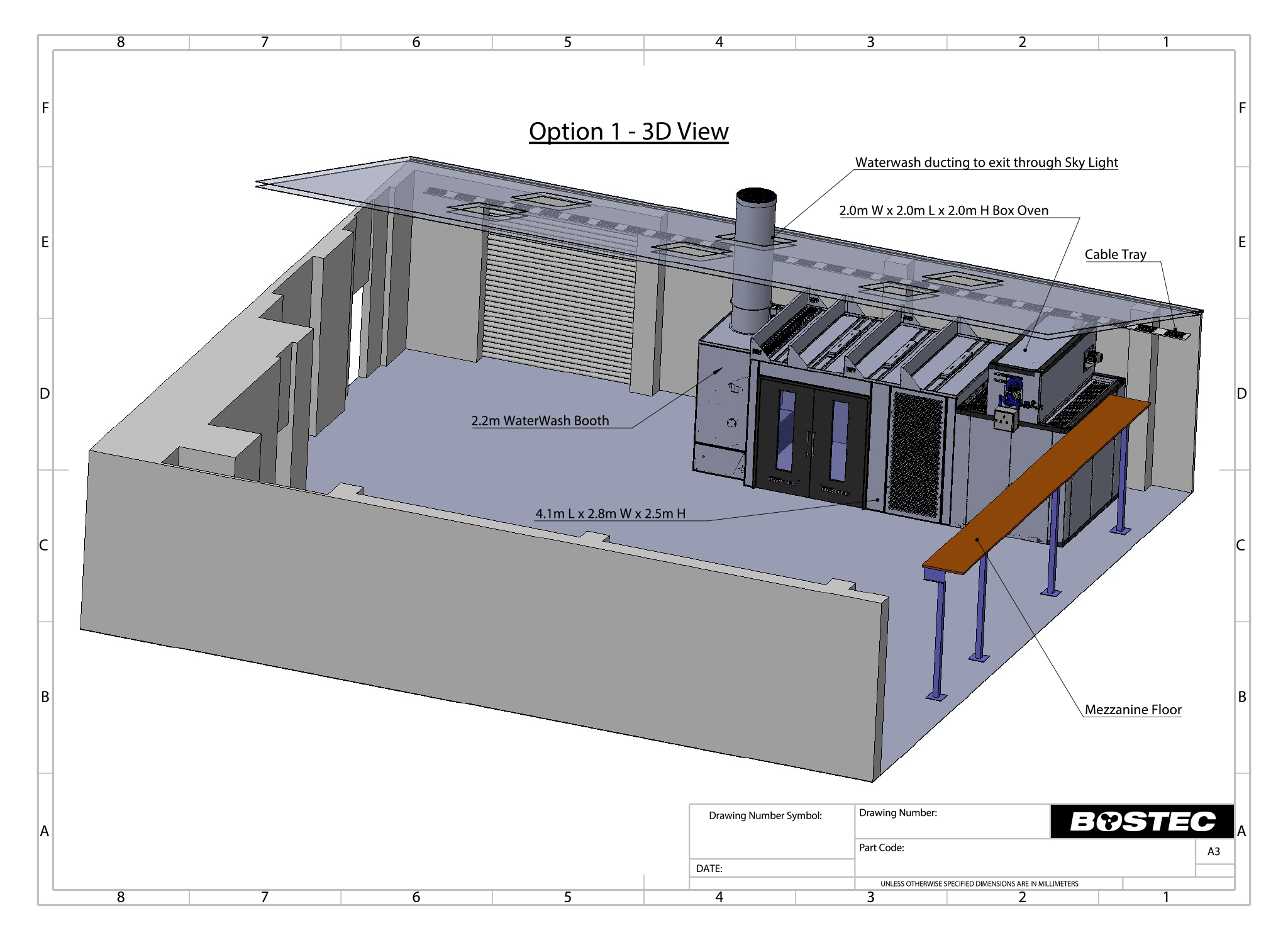

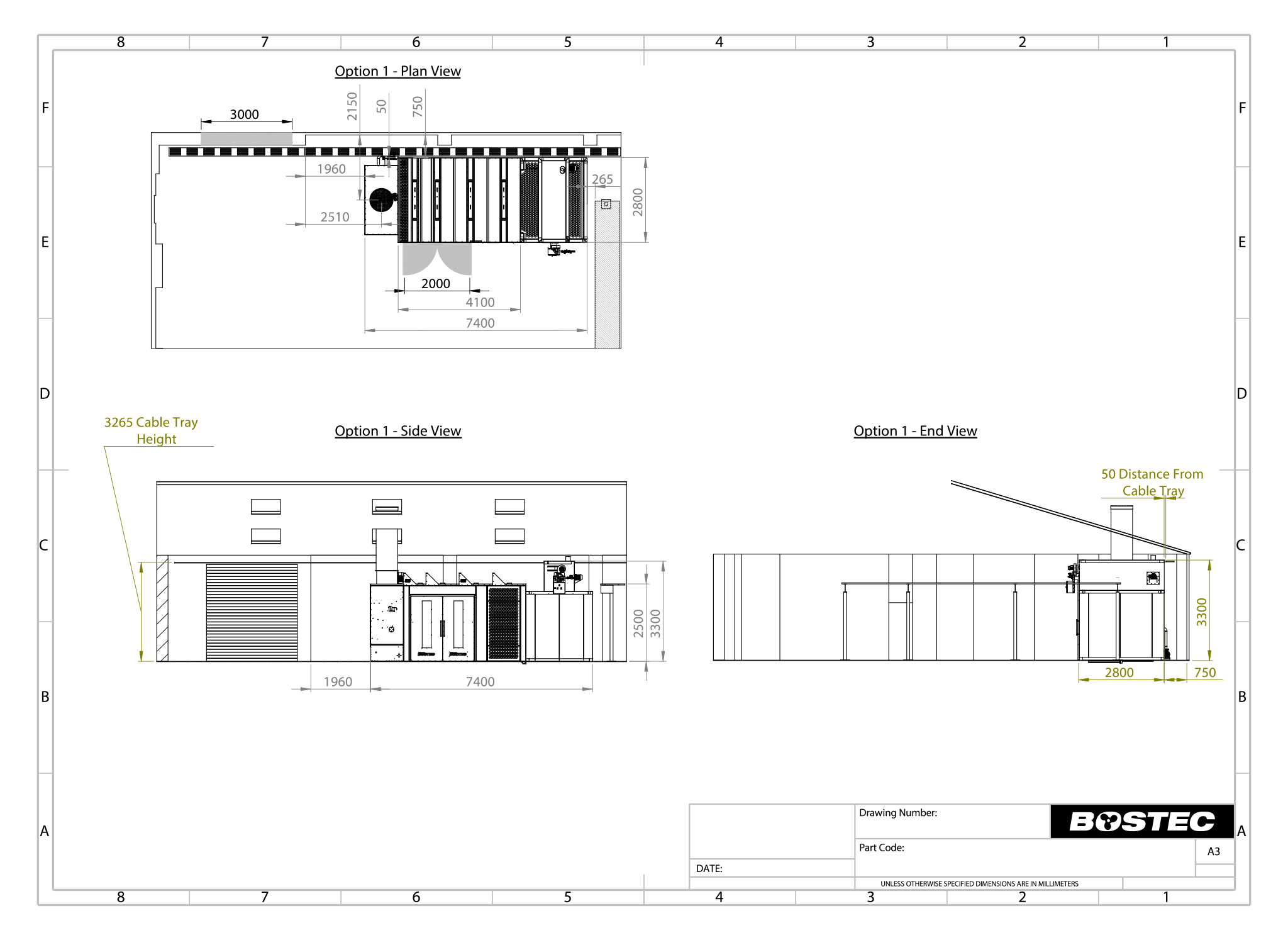

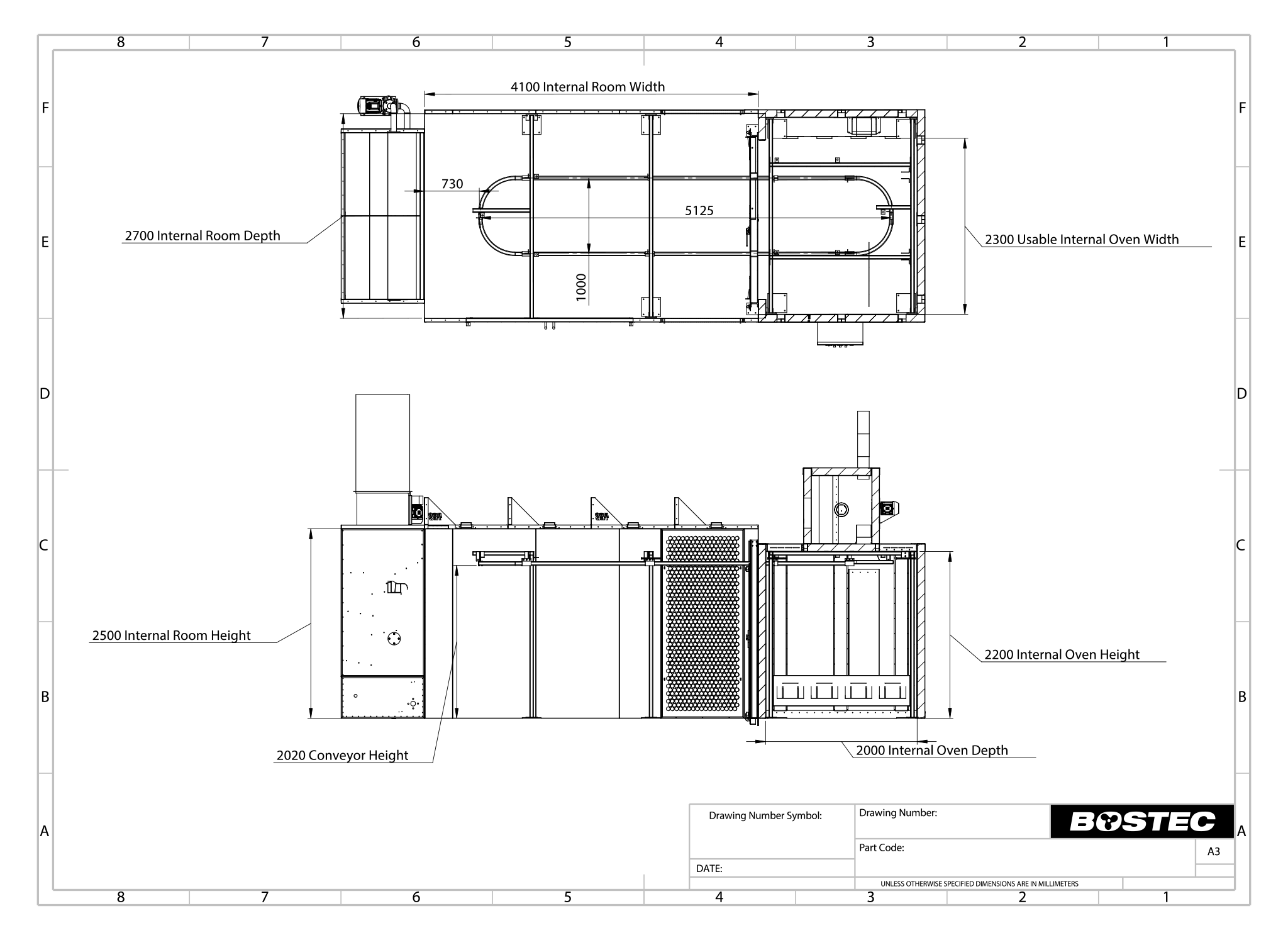

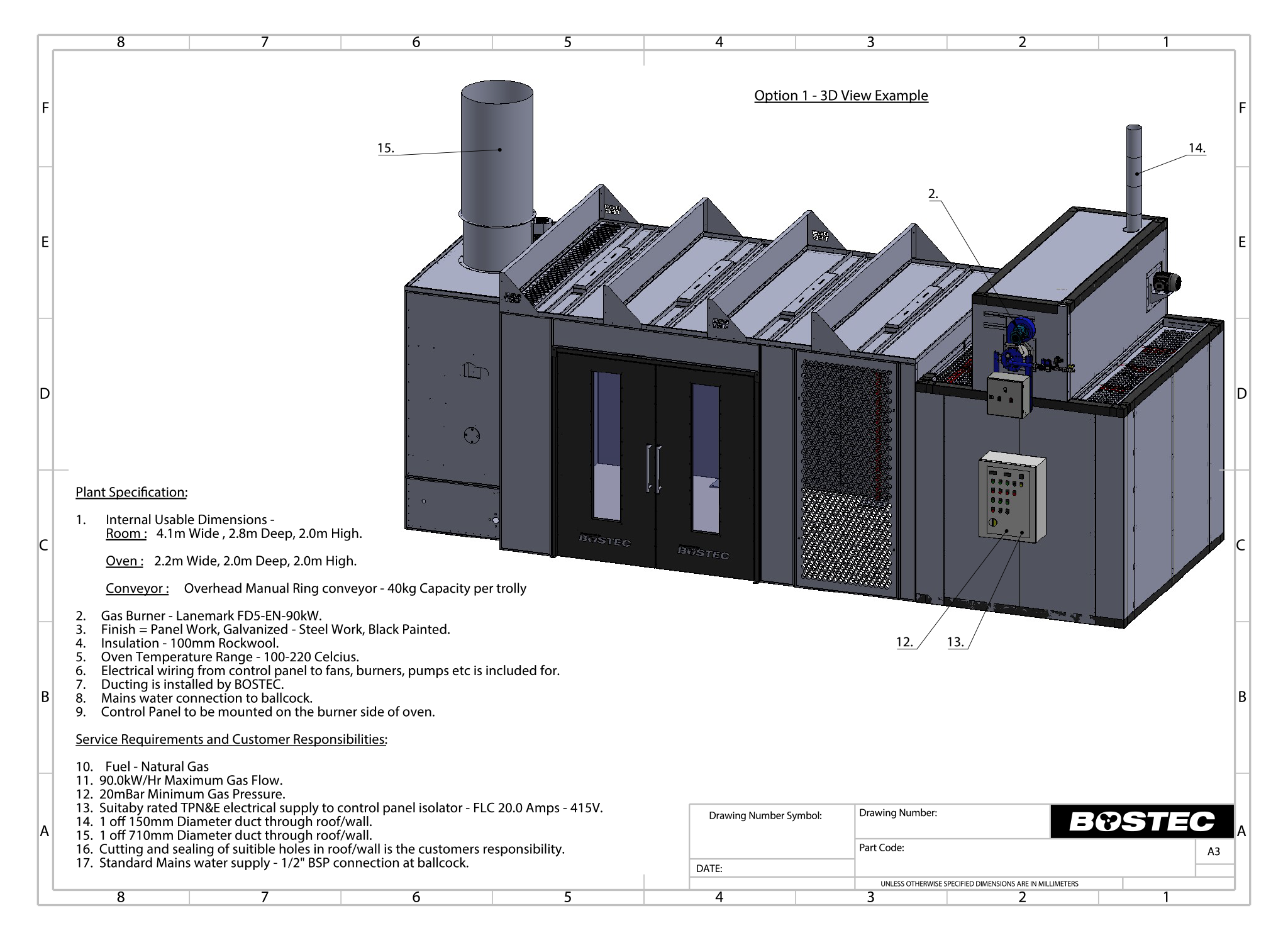

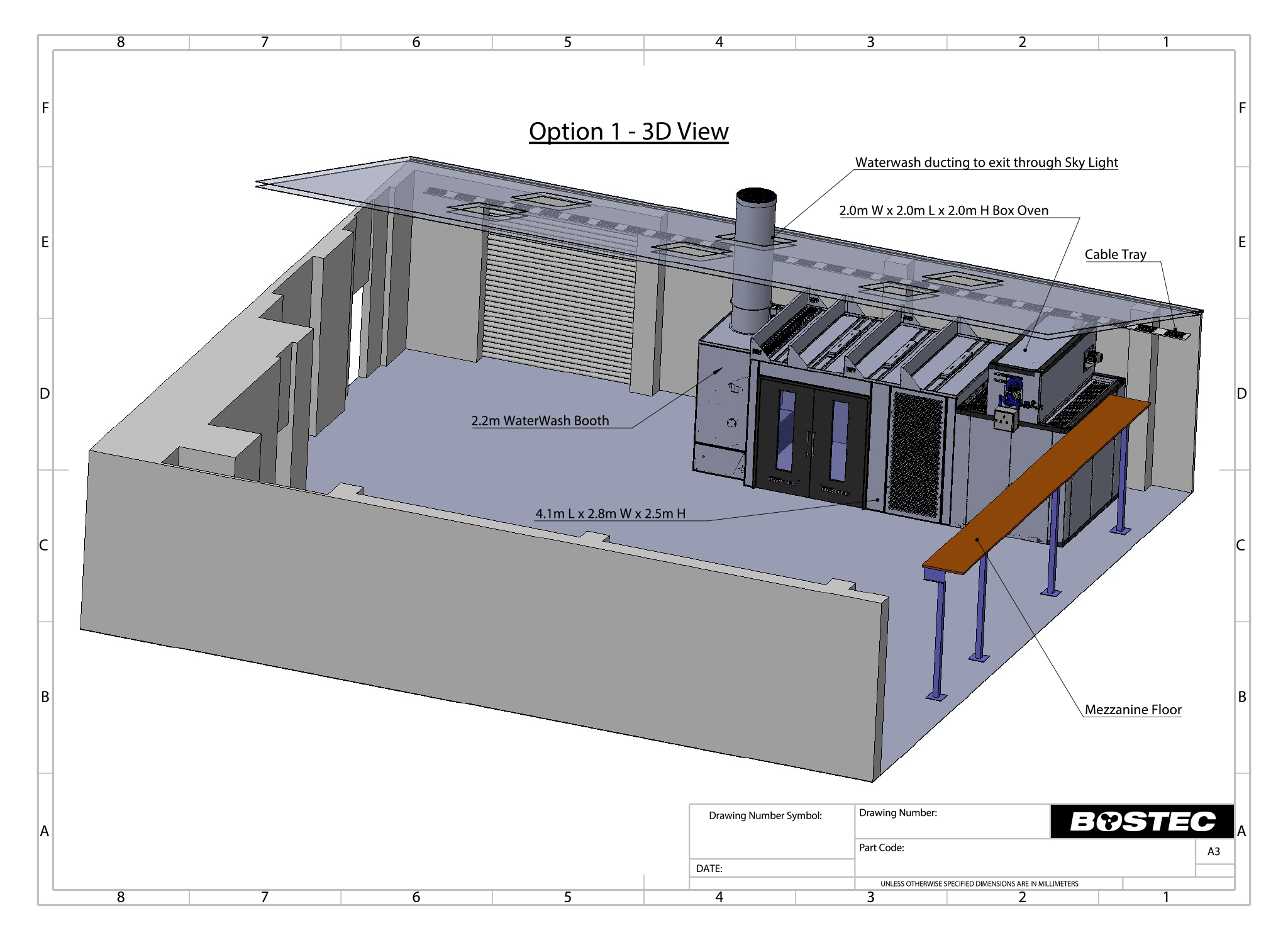

Alloy Wheel Plant Approval Drawings

The illustrations below show typical approval drawings, sent to our customers prior to manufacturing. These drawings are based on exact dimensions from the factory, with any visualisations giving a true and accurate representation of the real life measurements. These drawings aren’t just a guide for customers. They form the basis of our manufacturing, with all panels exported for cutting and fabrication. From the outset, we work closely with you to create a system that not only meets your immediate requirements but is also flexible enough to support your long-term growth. With customisable and scalable options, we ensure that your system can evolve as your business expands.

Alloy Wheel Plant Approval Drawings

The illustrations below show typical approval drawings, sent to our customers prior to manufacturing. These drawings are based on exact dimensions from the factory, with any visualisations giving a true and accurate representation of the real life measurements. These drawings aren’t just a guide for customers. They form the basis of our manufacturing, with all panels exported for cutting and fabrication. From the outset, we work closely with you to create a system that not only meets your immediate requirements but is also flexible enough to support your long-term growth. With customisable and scalable options, we ensure that your system can evolve as your business expands.

Alloy Wheel Machinery Design to Manufacture

Bostec oversee every stage of the manufacturing and installation process, from sourcing raw materials to final on-site integration, ensuring that each system is designed, built, and installed to meet the highest industry standards. We conduct a thorough pre-build site survey to verify that all components will fit as planned and identify any potential challenges. This can occur before the quotation or during the design approval stage for more complex projects. Using advanced precision tooling and working from detailed technical drawings, we fabricate all key components in-house. This level of control guarantees that every part of the system is meticulously checked for quality, fit, and finish before reaching your facility. We ensure seamless integration and reliable performance from day one.

Alloy Wheel Plant On Site Installation

Once manufacturing is complete, we manage the full installation of your system, ensuring a smooth integration into your facility. We take responsibility for every stage of the installation, including the integration of pneumatic systems and setup of spray equipment. Connection of gas and electrical supplies are generally handled by contractors. We can even arrange civil works and remove any existing plant equipment to ensure the smoothest possible transition for your facility. All work is carried out by certified professionals to the highest safety standards. After installation, we conduct commissioning tests to verify that every component functions as required. We provide comprehensive training sessions for your staff to ensure they are equipped with the knowledge and skills necessary to operate and maintain the system efficiently.

Alloy Wheel Refurb Project Photos

Extra Alloy Wheel Refurb Equipment

Alloy Wheel Refurb Tyre Removal

The first and last part of any refurb. Robust and simple to use and designed for those whose volume may not be that of a dedicated tyre shop, but who nevertheless want a quality product. This machinery allows for the removal of tyres and seperate balancing machine.

Alloy Wheel Refurb Wheel Straightening

Often one damaged wheel can make a complete set of alloy wheels irreparable. With this straightening rim lathe system the vast majority of bent wheels can be repaired quickly, with full training provided and installation available.

Alloy Wheel Refurb Wheel Paint Stripping

Place the wheels in an acid solution for a short period, then neutralise and rinse after carefully removing them. Recommended to be outside in a separate area. Price includes tank, chemicals, neutraliser tank, training, certification and PPE.

Alloy Wheel Refurb Wetblast Wheel Preparation

The final clean and prepare for the wheel before paint, this process washes away any paint residue and keys the surface ready for powder. This wetblast cabinet is plug and play, and can be seen in action in our video header above and in our start to finish video below.

Alloy Wheel Refurb Spray Booth

Capturing the over spray and removing it from the air, the spray booth can be open or completely enclosed to suit the workshop layout. Price above is for a combined spray room and oven, based on a popular and typical sizing for alloy wheel refurb businesses.

Alloy Wheel Refurb Powder Spray Gun

We only supply the best equipment with proven results, working alongside Gema, Wagner and Nordson to provide the very best powder coating application guns. We always recommend a minumum of two guns per alloy wheel refurb facility.

Alloy Wheel Refurb Curing Oven

LPG, gas or electric, these ovens heat up to temperature between 180 degrees and 240 degress celsius to degas the wheel. Pre-heat and cure at each coating cycle. Our box ovens are constructed with standardised modules, panels, heating and circulation components.

Alloy Wheel Refurb Diamond Cutting

Many modern wheels have a two-tone diamond cut finish. The simple to use pre-programmed lathe ensures a perfect finish every time, available in two sizes, upto 22 inch wheel and 28 inch. Windows based system and comes with training.

Air Compressors

Most of the equipment will require connection to a pneumatic air supply. Full installation of these systems is available as part of a turnkey package and full training is provided on all products by highly experienced industry experts.

Alloy Wheel Refurb from Start to Finish

Bostec Limited is a leading designer, manufacturer and supplier of product finishing solutions, with head offices and manufacturing facilities based near Oldham in Manchester. With over thirty years of experience in the product finishing sector, our core range of products includes bespoke spray booths, box curing ovens and tunnels, powder coating solutions and bespoke drying rooms, all supported by industry leading design and a dedicated aftersales team. We are approved Wagner powder system distributors and a Gema controls system house.